Pumps & Pump Stations

- Centrifugal Pumps Defined

- Pump Station Design

- Fixed-Speed vs. Variable-Speed Pumps

- Types of Pump Stations

- Vertical Turbines

- Canned Turbines

- Submersible Sleds

- Related Webinars

Our thanks go out to Boyd Rose of Watertronics, who provided the information and images for this article in his guest webinar, Pump Station Design.

Centrifugal Pumps Defined

Centrifugal pumps are machines for moving fluid by accelerating the fluid radially outward. A centrifugal pump incorporates an impeller rotating within a case (aka a diffuser). Liquid directed into the center of the rotating impeller is picked up by the impeller’s vanes, accelerated by the rotation of the impeller, and discharged by centrifugal force into the diffuser. A collection chamber in the casing converts much of the kinetic energy (energy resulting from velocity) into head, or pressure.

Centrifugal pumps' performance is affected by:

- Impeller thickness: The thicker the impeller, the more water will flow.

- Impeller diameter: The larger the diameter, the more pressure it will create.

- Rotation speed: The faster the impeller rotates, the more flow and pressure it will create.

Hydraulics in the piping system can cause the following issues:

- PSI drop

- Over-demand

- Varying inlet PSI

- Restrictions

- Pipe leaks

Pump Station Design

Because pump stations are automatic, they are fully controlled by the demand of the system they’re regulating.

Basic understanding of how a pump station should operate:

- Pressure drop initiates startup (remote signal or flow)

- Regulate pressure

- The right number of pumps running / demand

- Shutdown sequence

Characteristics of a well-designed pump station:

Mechanical:

- Properly sized components that match capacity

-

Piping layout that minimizes losses

- Fabrication and layout

- Proper use and application of sensing equipment

-

Materials of construction (cost and durability)

- Steel pipe and salt water

High voltage and controls:

- UL 508 listed or other certification

- The panel should have some type of cooling method

-

Type of panel is rated for the environment in which it’s installed

- Not just moisture but dust

-

Provides a level of personal safety

- Disconnect/interlock

- Appropriate complexity or simplicity for the application

Implementing pumps

- Pressurized (most common)

- Open discharge

Fixed-Speed vs. Variable-Speed Pumps

Fixed-Speed Pumps

Fixed-speed pumps have the following characteristics:

- Pressure switch on/off

- Hydraulic valve pressure regulation

- EBV pressure regulation

- No pressure regulation

- Constant speed motors/pumps

- Pressure control valve (added complexity)

- Full in-rush starting

- Pressure tank

- “Stair-step” horsepower

- “Foot on the brake”

Disadvantages of Fixed-Speed Pumps:

- Energy loss with control valve

- Control valve requires maintenance

- Zones need to match HP combos

- Pressure tank can be dangerous

In general, fixed-speed pumps are less efficient and require more maintenance.

Variable-Speed Pumps

Variable-speed, or variable frequency drive (VFD) pumps have the following characteristics:

- Electronic pressure regulation

- Varies speed of the motor

Advantages of variable-speed pumps:

- Varies the speed for pressure control

- Eliminates control valve and tank

- Low in-rush – easier on pipes

- Pulls only the power required to meet flow demand

- Less maintenance

- “Cruise control”

- 25% power savings

Types of Pump Stations

Note that the pump itself will remain the same across these various pump station types. The differences lie in the water source and the way the pump is applied and configured. The water source defines the pump station configuration.

Horizontal/Centrifugal

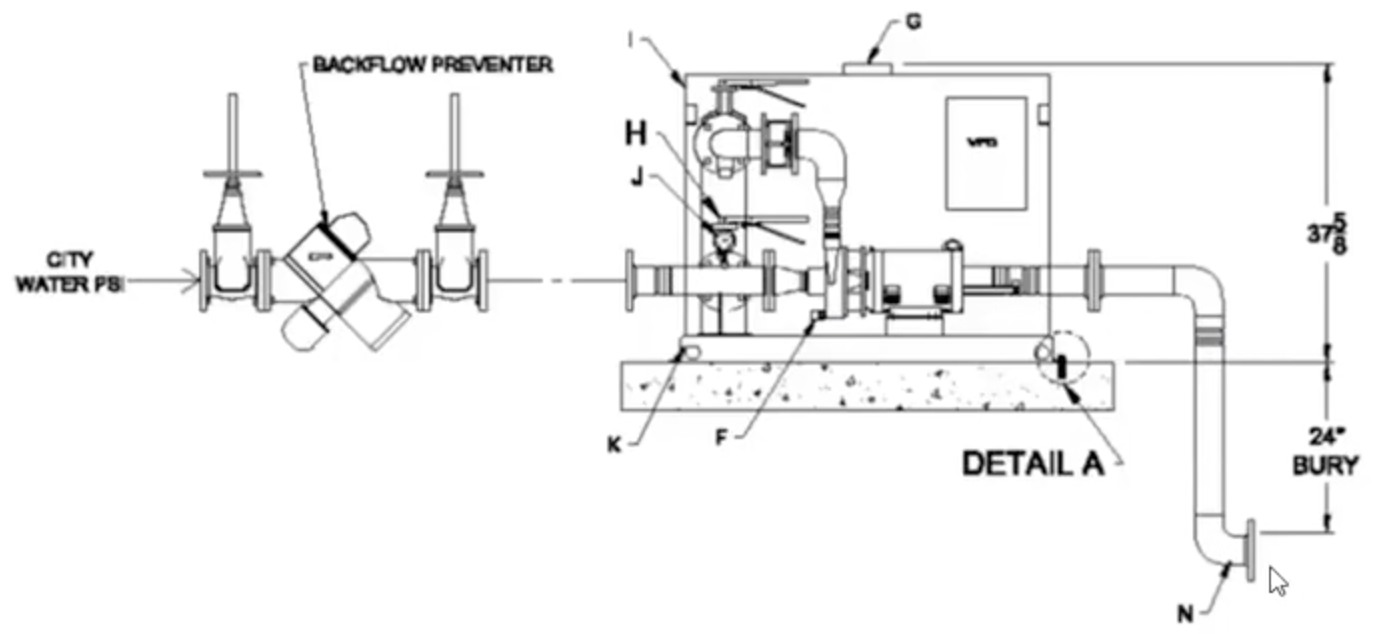

Booster (Pressurized Source)

A booster pump station is a typical city water application. It's the most common type of horizontal/centrifugal station. In this configuration, the pump boosts the pressure as it sends water out to an irrigation system.

Flooded Suction

The next-most-common horizontal/centrifugal station type is a flooded suction station. This system draws water from a tank or pond. The water source is higher than the inlet of the pump.

Suction Lift (Well)

In a suction lift well station, the pump is at a higher location than that of the source water.

Pros and cons of Horizontal Pump Stations (Booster, Flooded Suction, Suction Lift)

Pros:

- Least expensive

- Small size

- Easy access

- Parts access

Cons:

- Lower efficiency

- 3,600 RPM

- Marginal for dirty water

- Poor lifting capabilities

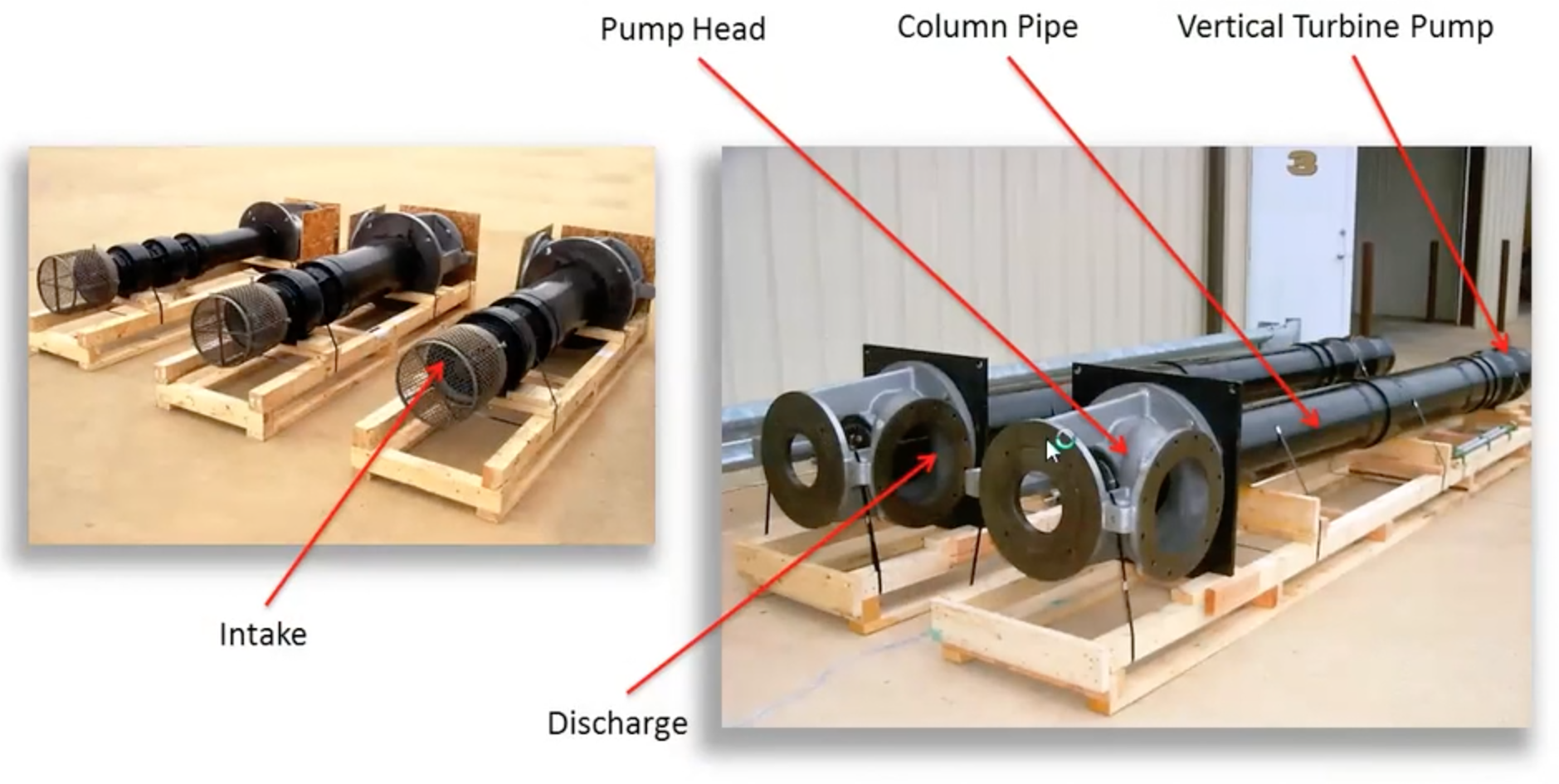

Vertical Turbines

A vertical turbine has multiple pump stages. The water goes in through an intake line through natural hydraulics and is pushed – not sucked – into a manifold and out into the irrigation system. Vertical turbines are commonly used in golf course irrigation.

Pros and Cons of Vertical Turbines

Pros:

- Most efficient

- 1,800 RPM – long life

- No “lift” issues

- Tolerant of dirty water

Cons:

- More expensive

- Requires a wet well

- Submersible pressure maintenance pump

- VHS motor is expensive to repair or replace

Canned Turbines

A canned turbine is a vertical turbine pump in a scenario where the water source (generally a cistern or pressurized collection) needs to be boosted.

Pros and Cons of Canned Turbines

Pros:

- Most efficient

- 1,800 RPM – long life

- Flooded suction but turbine efficiencies

- No wet well

Cons:

- More expensive

- Flooded or boost intake

- Needs a dry sump

- VHS motor expensive to repair or replace

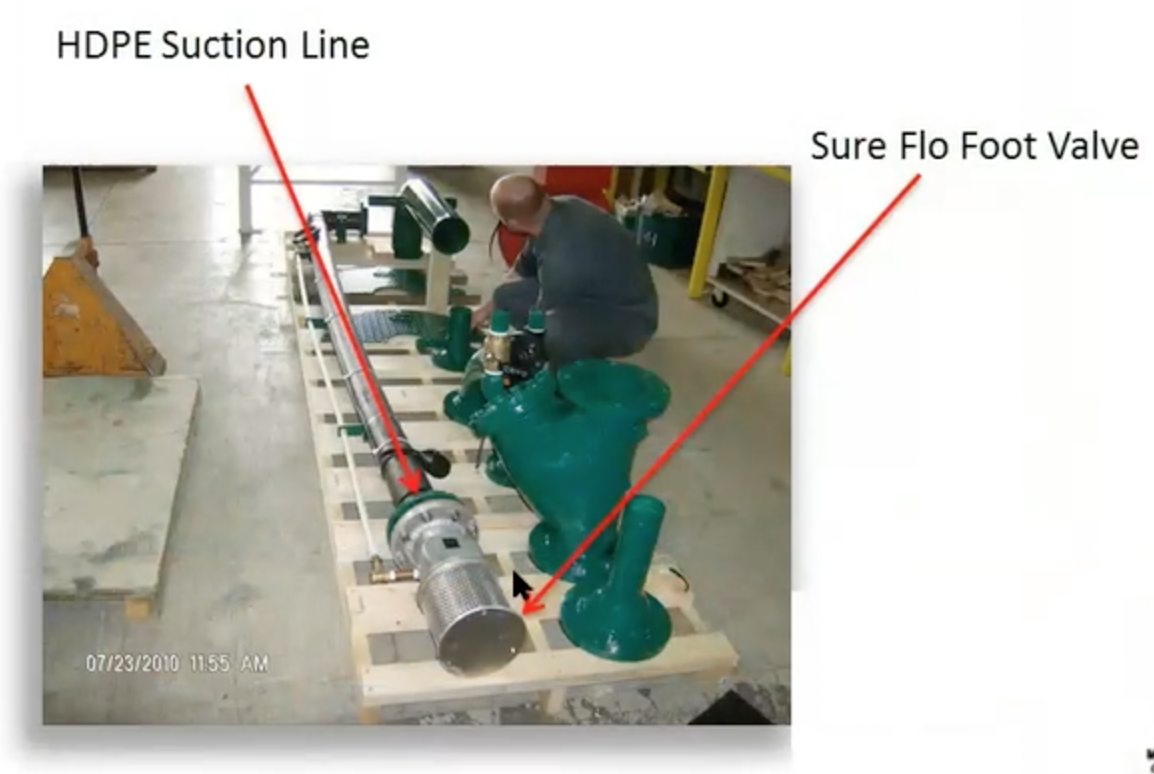

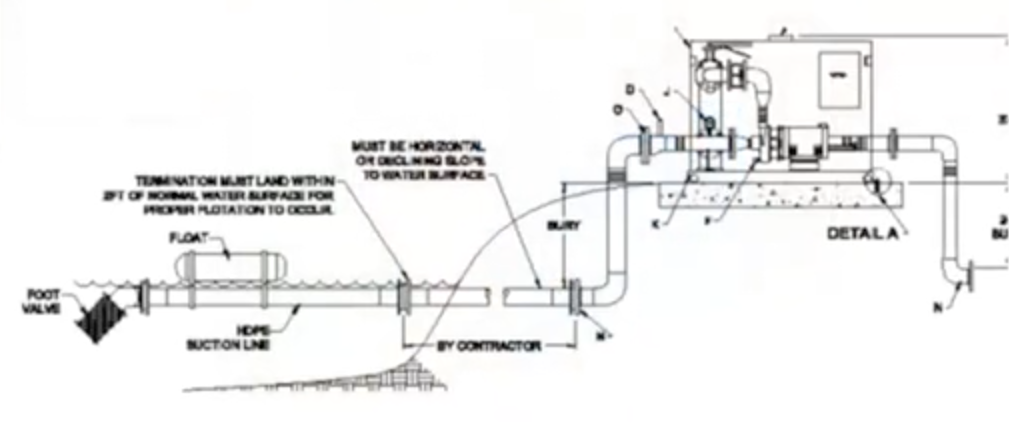

Submersible Sleds

A submersible sled is a structure on wheels that includes a submersible pump. It’s submerged in a water source such as a pond, river, or lake, and then pumps water out.

Pros and Cons of Submersible Sleds

Pros:

- Less infrastructure

- Low noise

- Common components

- No wet well

Cons:

- Setting and repair access more complex

- Must remove to service

- Must remove in winter

- Crane access can be a challenge

- Pump Station Design: Picking the proper pump can be an overwhelming task. Boyd Rose with Watertronics talks about basic pump design and how the type of pump you pick comes down to your water source. (1 hr 5 min)